Aluva ( Kochi) , KERALA :

The family-owned Mezhukkattil Mill, which manufactures edible coconut oil, stuck in through logistical and procurement issues to meet demand across the globe.

Kochi :

This is a rare Covid business story from Kerala — one about the grit and determination of a medium-sized edible oil mill in Aluva, near Kochi, to keep its mills running during the lockdown as its workers had no option but to stay put.

The decision was also fashioned by the demand surge during the early days of the pandemic when imminent lockdowns across the globe led to panic buying.

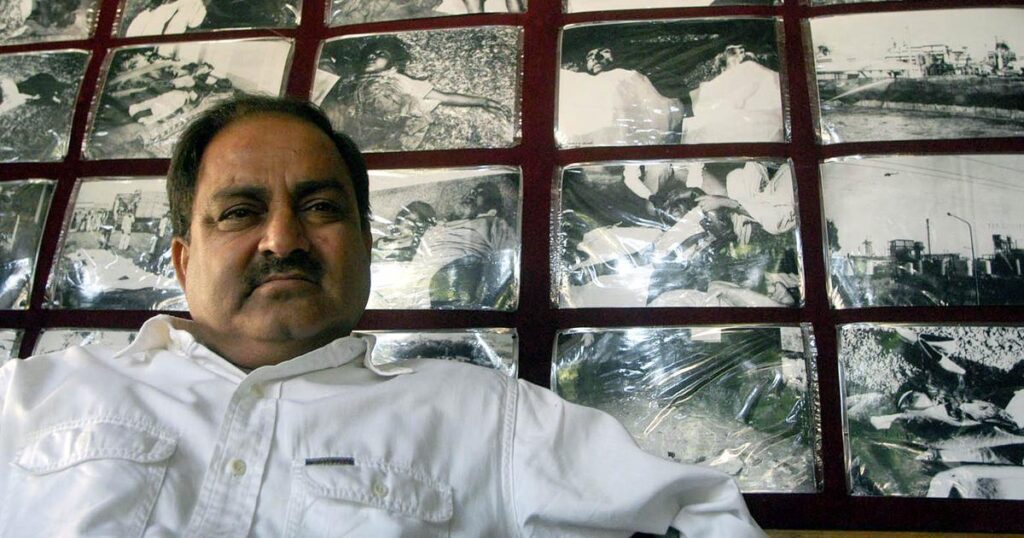

For Ubais Ali, executive director of the family-owned Mezhukkattil Mill, which manufactures coconut oil, it did not require theoretical lessons in business management or post-Covid strategies being peddled by major consultancies across the world.

All Ubais did was spot an immediate business opportunity when essential products began flying off the shelves across continents in the middle of March. He was alerted by business associates in the UAE, Saudi Arabia, Oman, Kuwait, Qatar and Bahrain that edible coconut oil, just like any other food item, was selling fast, with a large number of non-traditional users turning to this cooking medium.

But just as he began exploring the opportunity, lockdown was enforced in India on 24 March.

Ubais had about 50 workers in his factory premises who had no option but to stay put, but he had to contend with logistical issues.

“When the national lockdown began, we had three containers stuck at the Kochi International Container Terminal. Even the big players in the food processing sector were caught unawares as the clearing and forwarding agents of Kochi decided against taking any risk,” Ubais says.

“I had no option but to keep the mill running at full capacity with three eight-hour shifts as the big brands like Lulu said their malls (in the Middle East) were facing total depletion of stock. I had to take a chance or lose this opportunity forever.”

The logistical troubles

Such was the demand that towards the end of March, during the first phase of the lockdown, Ubais had to augment his supply line of six truckloads of copra, from Tirupur district in Tamil Nadu, with well over a dozen containers from Indonesia and Philippines.

That posed its own challenges. For one, the executive director had to battle for lorry passes from supply officers at the taluk level and also for inter-state travel permits.

Then the State Trading Corporation (STC) refused to issue the company with a no-objection certificate (NOC) for the import of raw materials to bridge the gap caused by the shortfall in the indigenous copra supply.

Ubais first attempted to sort this out through the Federation of Indian Exporters Organisation, of which he is a member, but eventually it required the direct intervention of the Director General of Foreign Trade (DGFT).

K.M. Harilal, joint DGFT, Kochi, said: “Though food processing units had an exemption from the lockdown, none were functioning in the first week. Ubais came to us with a peculiar problem, as he was not getting the mandatory clearance from STC for imports. As the company’s normal channel via Chennai was not fruitful I got through to my boss in Delhi who got in touch with the STC chairman and the NOC came through.”

But all the clearances in the world would not have helped in a city known for the sincere hands-down approach of workers during hartals and the lockdown, an occasion that demanded stricter adherence to stay away from work.

The export trouble

As if procuring raw material wasn’t hard enough, exporting the coconut oil provided an equally tough task, mainly due to confusion at the Cochin Port, the region’s main export transit point.

The Cochin Customs Brokers Association passed a resolution on 31 March that it would not move containers. It also sought clarification from the chief minister regarding anomalies in the notifications issued by the central and state governments.

The Ministry of Shipping had notified normal operations of ports and customs. It was the ministry’s advisory that all cargo, both general as well as essential, be cleared. The Kerala government, however, brought out an advisory that no one should be attending office except those specially notified. The state’s focus then was on health and avoiding any threat of contracting Covid.

Although the Cochin Customs Association withdrew its resolution following instructions from the customs commissioner, the overall sentiment among its members was more in line with the state government directive on ensuring personal safety.

As a result, there were no clearing agents ready to move the coconut oil consignments.

It posed a major hurdle for Ubais as based on demand from clients, his oil mill had lined up over a dozen containers for export by the end of April first week.

Finally, one agent, George Forwarders, expressed willingness to move the containers provided they did not face hassles from any departments. The mill and the agent both received a shot in the arm — one of the clients, to be precise the personal staff of M.A. Yusuff Ali, the UAE-based Indian billionaire businessman and owner of LuLu Group, promised to monitor all local clearances in Kochi.

The result: The first lot of three containers were moved in early April.

In all, between 25 March and 30 April, Mezhukkattil Mill imported 20 containers of raw materials for exports. And between 12 containers that came under the head of direct exports and seven containers of deemed exports, this little known company from Aluva managed to export 19 containers of finished products, earning around $ 6,68,000 (over Rs 5 crore) in foreign exchange.

The lessons for big business

For Mezhukkattil Mill, which was the largest supplier of coconut oil for soap and surfactant giants as also hair and skin oil in the 1990s, with a client list comprising Tata Oil Mills, Hindustan Lever, Wipro, among others, the lockdown has marked its coming of age. The mill had switched to manufacturing edible coconut in the decade between 2005 and 2015.

The company’s makeover as a manufacturer of only edible oil products is now complete. It now ships its oil for various brands such as Lulu Muscat Hypermarket LLC, Royal Mark Foods and Eastern Condiments in Oman and Panten Mee in Taiwan.

As the country looks to get its act together on the manufacturing front, stories from even small companies like Mezhukkattil could prove inspirational. Surely, instances like this depicting small and medium-sized companies punching way above their weight by pouncing on opportunities in a pandemic-struck market should stir the big players out of the present clime of gloom.

source: http://www.theprint.in / The Print / Home> Economy / by Vinod Mathew / June 02nd, 2020