Chennai, TAMIL NADU :

Bridlen, a family owned business from Chennai, on its Indo-Japanese collaboration to craft Goodyear welted shoes

Leather shoes, made to order, that fit like a glove, and look like a dream.

That is a rare luxury in a market dominated by e-commerce, where even designer brands are churning out collections by the season. For the true shoe connoisseur, only a customised product, can fashion a sartorial statement. So following slow food and slow fashion, now there’s a focus on slow manufacturing. At Bridlen, a shoemaking enterprise in Chennai that started in 1986, making Goodyear welted shoes the old-school way is a rich legacy that has continued into the 21st Century.

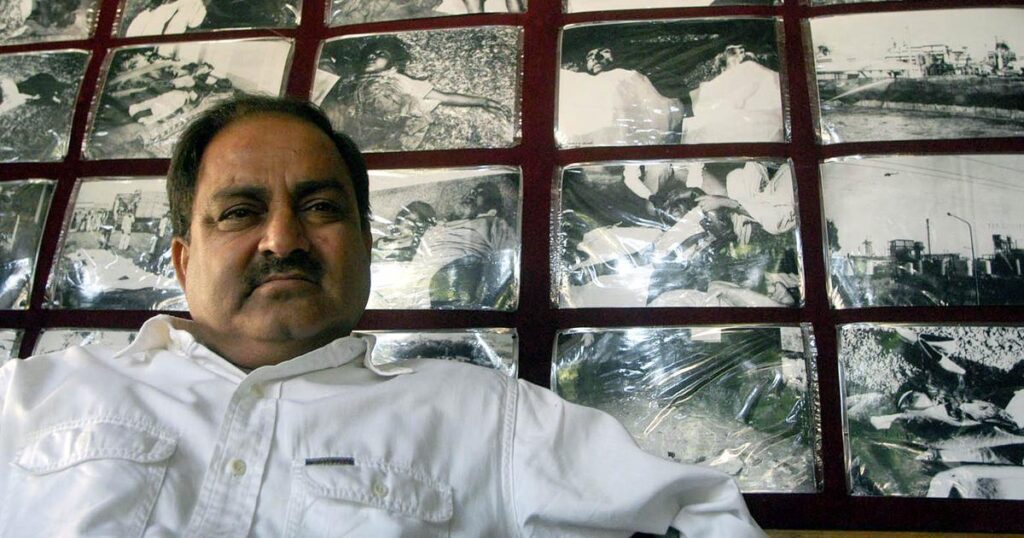

Started by the late K Mohamed Hasan, who began his career in shoemaking with solely creating uppers , he then turned his eye to create not just custom shoes, but footwear that would please, whom he considered the most discerning customers — the Japanese. As a first-generation shoemaker with clients in the UK, France, Italy, Germany, Switzerland, Spain and Portugal, he found a friend in Jose Maria Watanabe, a Japanese shoemaker with four decades of experience in the business. What started as a unique friendship, then turned into a partnership that coalesced the best of Japanese design and Indian craftsmanship.

_____________________

How its made…

A Goodyear welt is a strip of leather, rubber, or plastic that runs along the perimeter of a shoe outsole. The machinery used for the process was invented in 1869 by Charles Goodyear Jr., the son of Charles Goodyear, American engineering manufacturer and inventor of vulcanised rubber. Charles’s son followed in his father’s footsteps and came up with a manufacturing process that could be used to assemble various parts of a shoe. Using a process called hand welting the upper portion of the shoe would be sewn together with the sole using a boar’s bristle needle and waxed thread.

__________________

The Japanese connect

Following the untimely demise of its founder in 2019, Bridlen is now managed by his son, Mohamed Affan Kolandaiveedu. Affan explains why their Goodyear welt design is a cut above the standard, “ We don’t attach a cotton rib to the insole. We take a channel on a much thicker insole and stitch the welt to that. This is what separates us from most other brands at our price point or even a few brackets above. A search on the authorities of the classic shoe world from Simon Crompton at Permanent Style or Jesper of shoegazing.com have singled out this feature as a point of strength, something that you don’t normally find on factory made shoes,” explains Affan.

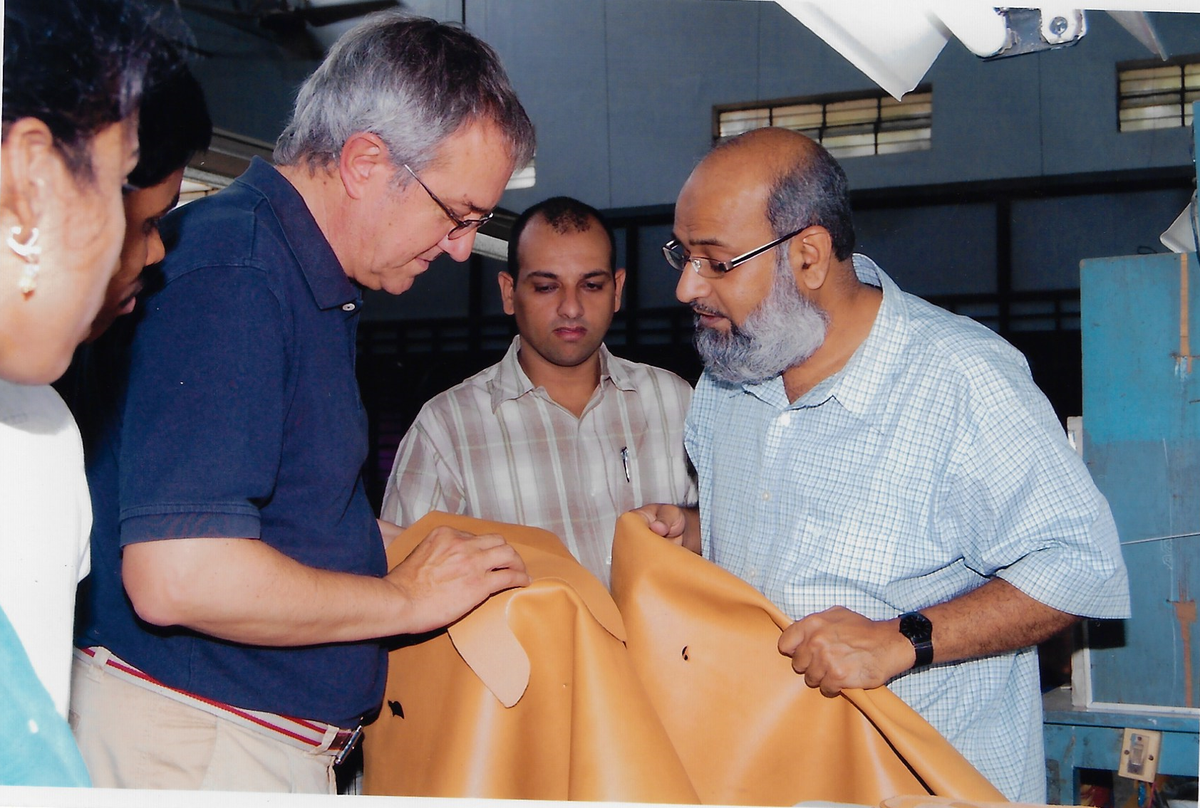

The story of Bridlen is fashioned by an Indian team guided by Watanabe. A Goodyear welted shoemaker based in Spain, he worked with a European partner, and was looking for a manufacturing capacity closer to Japan, when he heard about a small factory in India and came to visit. “Watanabe and Hasan really hit it off with their philosophy for quality, ethics in business and demeanour that they decided to do something together even though the original plan to move the Spanish production to India did not work,” states Affan.

Watanabe looked to pass on his skills, to Indian craftsmen who were serious about preserving the trade. “My project with Affan Shoes was the production of a finished shoe, something they had never experienced before, and at the same time it was a quality standard that was accepted worldwide.” Explaining how his mentor acclimatised to the new workspace, he adds, “Watanabe took great pains in the early days to get along with the workforce in our factory. He learnt a bit of Tamil and taught basic Japanese to some of the staff and their children on weekends. He would spend half the year in Chennai, and loved to partake in social gatherings, our festivals, and cultural practices.”

Pandemic pivot

Watanabe has continued his association with Bridlen, even during the pandemic. Until three days before the first lockdown came into effect in March 2020, Watanabe was in Chennai, and managed to get one of the last scheduled flights out of New Delhi to Tokyo. “We were in touch with him at least once or twice a week through video calls,“ says Affan, adding how the pandemic forced Bridlen to look at doing fittings remotely. The brand took to e-consultations where a potential client could book a video consultation to understand fitting. For clients who ordered a pair of Goodyear welted shoes online, a pair of fit-trial shoes would be shipped to them, to ensure the sizing was right before making it in their preferred style/ colour. “This gave clients a much needed boost in confidence to try a new brand and to speak with someone from the team about the intricacies of wearing them, the break-in period, shoe care etc,” states Affan. Post lockdown, the styling at the brand has pivoted as well, from classic to casual classics, bringing sustainable Goodyear construction to a wider variety of footwear styles: chukka boots, derbies, or semi-formal loafers.

Watanabe, who is currently in Tokyo, says working in India has been a rewarding journey. “Even though we made small batch production runs, it was important for Watanabe that these shoes should be available to a wider audience in terms of affordability.”

While the goodyear welted shoes range between ₹15,000 ($200) and ₹25,000 ($310) depending on specification, the construction remains the same.

All eyes on India

The craft on display at Bridlen, has kept the shoemakers competitive in the luxury shoe segment in India and Japan, followed by USA, France and Germany, a testament to the foresight of its founder, Affan states. Affan, who calls himself a shoemaker at Bridlen, has carried forward his father’s legacy and is optimistic of his business prospects across the globe, adding, “Our economy and labour market, now, and going into the future, are geared more towards higher value-added manufacturing or services. If you want good quality production, limited batch runs, attention to detail, then India could still prove to be a good place for international brands.”

With international travel picking up steam, Bridlen has been showing its collections at trunk shows in New Delhi in March and London in May. The tour continues with Mumbai in July, Bengaluru and Hyderabad in August, Stockholm and Paris in September and Amsterdam and Kolkata in October.

As India’s upwardly mobile middle class looks to buy custom footwear, with wearability, quality, sustainability and longevity guiding purchases, Affan wants his shoes to be the natural choice. “In Australia, you have RM Williams as a rights-of-passage bootmaker. In England, there are Crockett and Jones, Churchs, in the USA, there is Alden; that when you come of age, get to a certain job profile or income level then you aspire to own a few pairs of these shoes. We want to be that brand for Indians!

Box- ALL ABOUT THE LEATHER

Almost all the leathers used at Bridlen are imported from France, Italy or the UK “where strict norms for effluents are followed, source-tracing is available, and all compliance norms are met. Where made locally, like the lining leathers, we use LWG (Leather Working Group) certified, owner- driven micro tanneries where we know they are serious about meeting our local statutory environmental and sustainability laws.

“In Europe, the demand for high quality shoes, by extension for high quality leather has been there for a long time. So tanneries have been catering to this demand for quality for decades. Minimum order quantities are not as high when compared to the good tanneries in India where their expectation is much higher. In India it’s an uphill task to convince a tanner to do smaller quantities of higher quality because the industry is geared towards making more volumes to feed the bulk production shoe factories,” says Affan.

source: http://www.thehindu.com / The Hindu / Home> Life & Style> Fashion / by Anisha Menezes / September 17th, 2022